Movable Vacuum System

Price 10000 USD ($)/ Unit

Movable Vacuum System Specification

- Condition

- New

- Heating Capacity

- Up to 5 kW

- Control Mode

- Digital PID Control

- Heating Method

- Electric Heating with Vacuum

- Accuracy

- 1C

- Power Source

- Electric

- Type

- Movable Vacuum System

- Model

- MVS-904

- Internal Size

- 700 x 500 x 900 mm

- External Size

- 900 x 600 x 1200 mm

- Volume

- Approx. 315 Litres

- Air Flow

- Adjustable, Vacuum Pump Driven

- Temperature Range

- Ambient to 200C

- Material

- Stainless Steel 304

- Dimension (L*W*H)

- 900 x 600 x 1200 mm

- Power

- 4.5 kW

- Voltage

- 220-240 V / 50 Hz

- Surface Finish

- Polished/Satin

- Shelf Material

- Removable Stainless Steel Trays

- Safety Features

- Overheat Protection, Vacuum Relief Valve

- Mobility

- Mounted on Lockable Castor Wheels

- Vacuum Level

- Up to -0.098 MPa

- Noise Level

- Less than 70 dB

- Display

- Digital Temperature and Vacuum Gauge

- Application

- Suitable for Laboratory, Pharmaceutical and Industrial Use

- Operating Environment

- 5-40°C, RH < 80%

- Chamber Door

- Silicone Gasket Sealed Hinged Door

Movable Vacuum System Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Day

- Delivery Time

- 60 Days

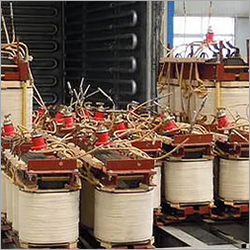

About Movable Vacuum System

Description : This system is applicable for evacuating large transformers or for maintaining large transformers on site. It can operate normally without cooling water due to perfect vacuum pump. So it is especially suitable for site working without cooling water source or for large transformer unmovable. All parts are mounted on a movable trolley, integrated controlling cabinet with 30 meter cables. Configured with top brand pump, stainless pipeline, manual ball valve and mini compressor, the whole system is compact and convenient for outside work.

Precise Control and Reliable Safety

Equipped with digital PID controllers, the MVS-904 ensures consistent temperature accuracy (1C) and vacuum conditions throughout the processing cycle. Enhanced safety is provided by integrated overheat protection and a vacuum relief valve, safeguarding both operators and sensitive materials during operation.

Mobility and Flexible Application

Mounted on lockable castor wheels, the system is easily moved and securely positioned anywhere within laboratories or production facilities. Its versatile capacity (315 litres) and wide operating temperature range (ambient to 200C) make it suited for a variety of drying, curing, and material treatment processes.

Designed for User Convenience

Featuring a hinged, silicone gasket sealed door and removable stainless steel trays, the system allows easy access and cleaning. The external size (900 x 600 x 1200 mm) and polished or satin stainless steel finish ensure durability and compatibility with demanding environments.

FAQs of Movable Vacuum System:

Q: How does the Movable Vacuum System ensure accurate temperature and vacuum control?

A: The system uses a digital PID controller that precisely regulates temperature (1C accuracy) and vacuum levels, both of which are continuously displayed on digital gauges. This reliable control ensures optimal process conditions for delicate laboratory and industrial applications.Q: What safety features are included in the MVS-904 model?

A: Safety is prioritized with overheat protection and a vacuum relief valve, preventing hazardous pressure build-up and temperature excess. These features help protect users and maintain process integrity, especially when working with sensitive substances.Q: When and where can the Movable Vacuum System be used?

A: The unit is designed for laboratory, pharmaceutical, and industrial environments, suitable for processes like drying, curing, and material testing. It operates efficiently in locations where a temperature range from ambient to 200C and a controlled vacuum atmosphere are required.Q: What is the process for loading and unloading samples into the chamber?

A: Samples are placed on the removable stainless steel trays inside the chamber, accessible via the silicone gasket sealed hinged door. After process completion and chamber venting, trays can be easily removed for unloading and cleaning.Q: How does the system benefit users in laboratory or industrial settings?

A: The MVS-904s mobility, high capacity, precise control, and safety features facilitate efficient sample treatment. Its quiet operation (<70 dB) and user-friendly design reduce workflow disruptions while ensuring reliable performance.Q: Can the airflow and vacuum be adjusted for different material requirements?

A: Yes, the system offers adjustable airflow and vacuum pump control, allowing users to tailor conditions to specific material properties, optimizing drying or curing results for varied process needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Vacuum Equipment Category

Dry-Type Transformer Vacuum Epoxy Resin Casting Plant

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 3300 x 1800 x 2200 mm

Accuracy : 1C

Voltage : 380V / 415V

Material : Stainless Steel & Carbon Steel

Transformer Test System

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 1800mm x 950mm x 1800mm

Accuracy : 1C

Voltage : 380V

Material : Cold Rolled Steel

variable pressure vacuum drying furnace for transformers active parts

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 , , Unit

Dimension (L*W*H) : Varies by model and requirement

Accuracy : 2C temperature accuracy

Voltage : 380V/415V/440V, 3 Phase, 50/60 Hz

Material : Mild steel with hightemperature resistant insulation

Industrial Vacuum Drying Oven Heating By Gas Burner For Transformer Drying

Price 10000 USD ($) / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : As per client specifications

Accuracy : 1C

Voltage : 380 V / 415 V / 3 Phase

Material : High grade steel (Inner chamber: stainless steel, Outer: Mild steel)

Send Inquiry

Send Inquiry