Equipment For Vacuum Pressure Impregnation - VPI Equipment

Product Details:

10000.00 - 100000.00 USD ($)/Set

X

Equipment For Vacuum Pressure Impregnation - VPI Equipment Price And Quantity

- 10000.00 - 100000.00 USD ($)/Set

- 1 Millimeter

Equipment For Vacuum Pressure Impregnation - VPI Equipment Trade Information

- 10 Millimeter Per Day

- 60 Days

Product Description

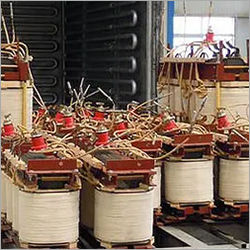

Equipment for vacuum pressure impregnation - VPI Equipment

Equipment Description

This kind of equipment is mainly application of insulation processing for electrical products, such as high voltage motor, generator, H class dry type transformer, power capacitor, cable insulation, and motor repairing, etc. For example, coil winding of motor or transformer can be evaporated at vacuum condition to reduce influence from moisture, air or other impurities. With pressure imoregnation, resin can be immersed into inner side to make the high insulation class. VPI equipment is also used in material industry for improving material performance.

What Is Vacuum Pressure Impregnation (VPI)

Vacuum Pressure Impregnation (VPI) is a process that uses vacuum and pressure to seal porous materials with varnish or resin. The process is used primarily for high-voltage motors and generators to fill gaps in materials to create a void free insulation in various devices.

Industrial electromechanical equipment is designed for durability to provide reliable function and increased longevity, but age, temperature, and environmental factors can degrade porous metals over time. The process of impregnation seals porous materials with varnish or resin, improving the function and longevity of equipment.

Technology Advantage

Equipment Description

This kind of equipment is mainly application of insulation processing for electrical products, such as high voltage motor, generator, H class dry type transformer, power capacitor, cable insulation, and motor repairing, etc. For example, coil winding of motor or transformer can be evaporated at vacuum condition to reduce influence from moisture, air or other impurities. With pressure imoregnation, resin can be immersed into inner side to make the high insulation class. VPI equipment is also used in material industry for improving material performance.

What Is Vacuum Pressure Impregnation (VPI)

Vacuum Pressure Impregnation (VPI) is a process that uses vacuum and pressure to seal porous materials with varnish or resin. The process is used primarily for high-voltage motors and generators to fill gaps in materials to create a void free insulation in various devices.

Industrial electromechanical equipment is designed for durability to provide reliable function and increased longevity, but age, temperature, and environmental factors can degrade porous metals over time. The process of impregnation seals porous materials with varnish or resin, improving the function and longevity of equipment.

Technology Advantage

- Easily evaporate moisture and air

- Residual water rate less than 10ppm, good insulation performance

- Good humidity resistance

- High dielectric property

- Resin materials recycle use

- High efficiency with good quality

- Integrated pressure vessel, vacuum, pressurization, cooling,heating and automatic controlling

- PLC controlling and touch screen operating

- Equipment with safety alarm and interlock protection device

Enter Buying Requirement Details

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese